Pharma

Dyssol enables QbD and continuous manufacturing by time-dependent dwell times and the ability to predict product quality

Dyssol helps engineers simulate and optimize solids processes – from pharma to mining – with multidimensional particle properties.

Simulate a spray dryer process with inlet temperature 180°C and feed rate 100 kg/h...

Our partners and users

Dyssol is an attractive tool for our solids production processes to gain a deeper understanding and to push our operations to their limits. With DyssolTEC, we have found a strong partner for future cooperation!

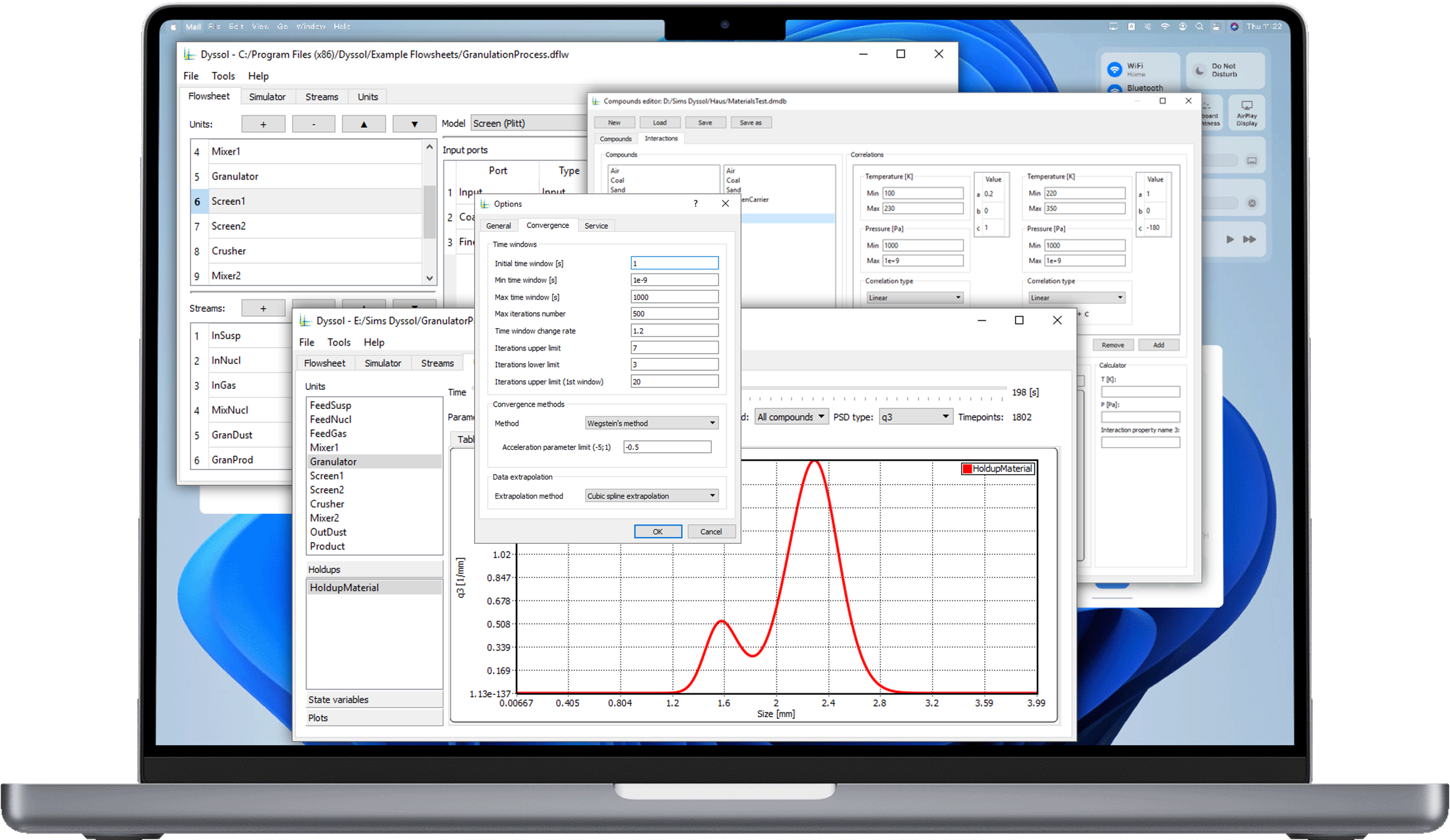

Flowsheet simulation is used to describe production processes, optimize them, develop control strategies or design new products. The flowsheet simulation software Dyssol focuses on modelling solids processes.

The challenge here is to display all solids properties and their interactions as size, shape or moisture, which Dyssol can handle by design. In addition, the modelling framework allows the simulation of dynamic processes to investigate stability, start-up and shut-down behavior in continuous, batch and semi-batch modes.

The flexible dynamic models and customization options make Dyssol the perfect solution for process simulation

Dyssol enables QbD and continuous manufacturing by time-dependent dwell times and the ability to predict product quality

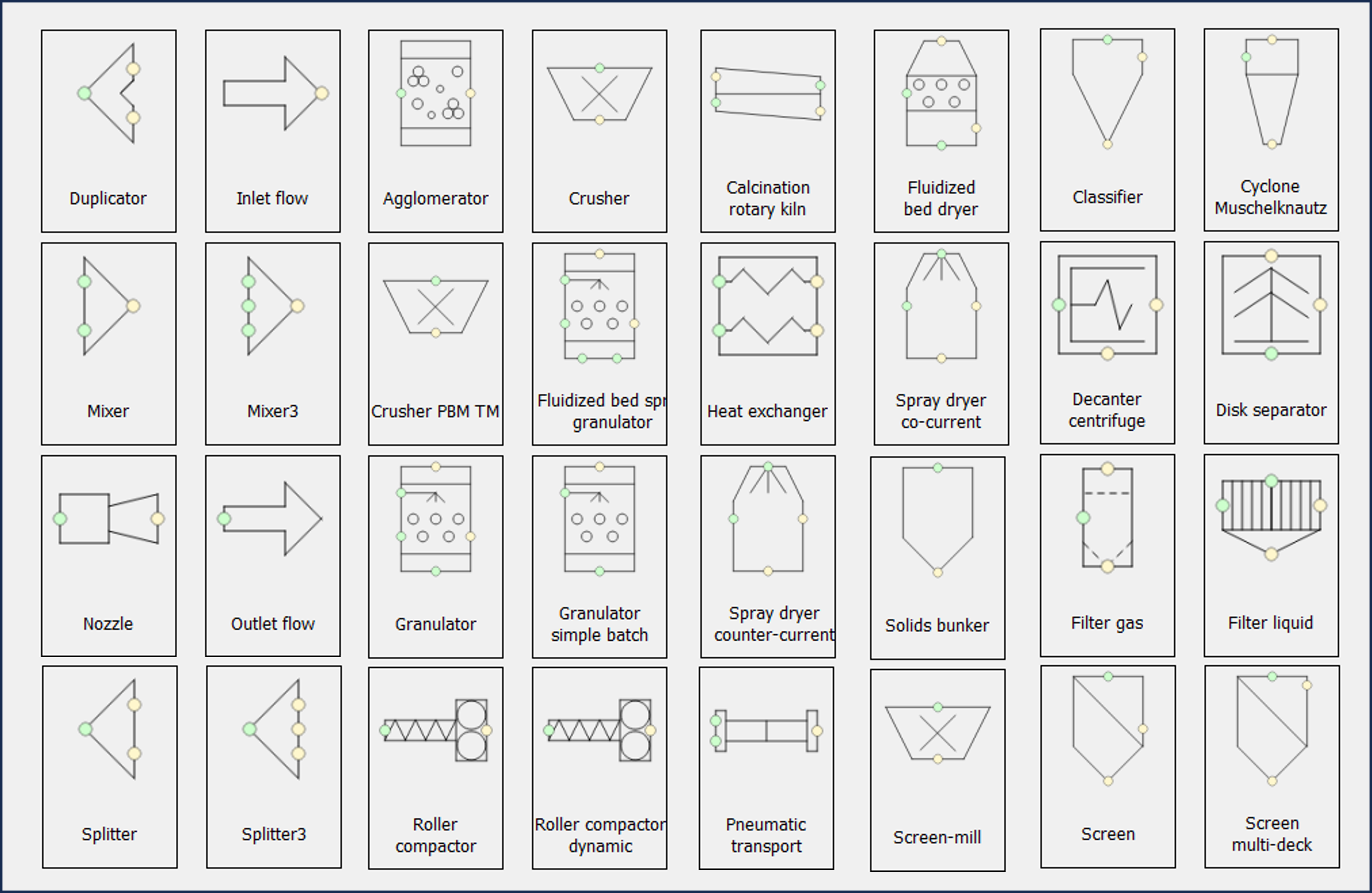

Many downstream processes like crystallizer, spray dryer, and fluidized beds are already implemented

Process units like spray dryer, crystallizer, granulator, agglomerator and separator are included

Many comminution and separation units are available

Dyssol comes with a set of base process models for drying, size change, storage, transport and separation, already implemented and ready-to-use.

Everything you need for advanced solids process simulation

Dyssol enables multiple bulk properties besides the size distribution and their interaction.

The basis version of Dyssol is and will stay free to use for everybody.

Consider time-dependent process behaviour including batch, semi-batch, start-up and shut-down.

Base process models for drying, size change, storage, transport and separation ready-to-use.

Design your specific process using the intuitive Drag&Drop flowsheet designer.

Use our Model Maker to build your own models that perfectly represent your processes.

DyssolTEC provides comprehensive services around the flowsheet simulation software Dyssol

Help with installation, introduction to the simulation system, implementation of new models, databases or interfaces to customized Dyssol versions

We can develop and implement custom models for your specific processes in your own licensed Dyssol version

Workshops and trainings (on-site and online) customized to your specific needs

Sign up to receive the latest news about Dyssol and DyssolTEC